TheMotor

Today’s motor designs are based on inaccurate heuristics (half-truth rules of thumb).

And, major advances in motor design have been missed.

“TheMotor” is a new motor design that is a major advance. The half-truth heuristics that have dominated motor design are:

#1 Use magnetic-field generating geometries as highly effective heat transfer devices.

#2 Use magnetic field generating geometries to tolerate higher temperatures.

#3 Design motors at high flux densities of stator-rotor interfaces.

- Permanent magnet motors are more efficient than induction motors.

- Design the motor around conventional coils.

#1 Use magnetic-field generating geometries as highly effective heat transfer devices.

#2 Use magnetic field generating geometries to tolerate higher temperatures.

#3 Design motors at high flux densities of stator-rotor interfaces.

|

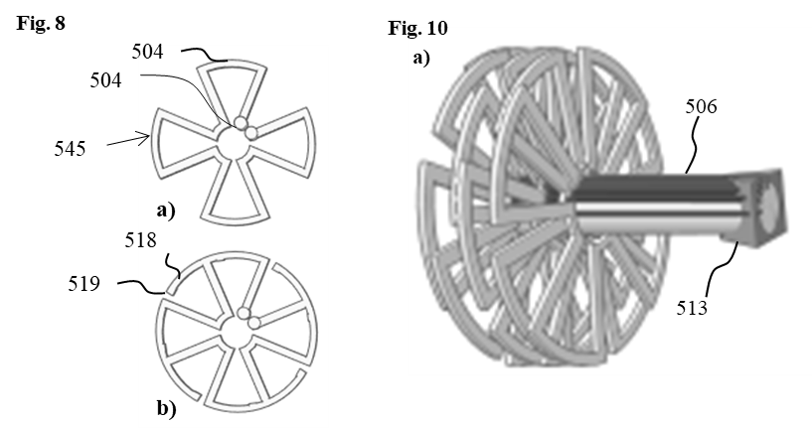

Fig. 8 of Patent Application PCT/US22***** (also see PCT/US21/16392 and PCT/US20/36936) illustrates geometries that achieve heuristics #1 and #2; these geometries do not have insulation buried in coils (insulation is only on the heat transfer interface); buried insulation: a) increases heat transfer coefficients and b) places the insulation on the coolest part of the device (next to the heat transfer fluid). These stator designs have significant increases in rate of heat transfer and maximum sustained temperatures of operation. As a result, much higher current fluxes can be sent through the circuits which can reduce the mass of copper by 50% to 80% in the motor.

|

These thin stator designs allow field-generating circuits to be stacked in phased configurations such as that shown by Fig. 10. Multiple rotor discs can be placed in this axial-flux stacked-disc configuration to increase the density of rotor-stator interfaces by 2X to 5X; this increases the power density by a similar factor.

The energy densities are much higher than contemporary designs.

Also, significant reductions in Eddy-current losses are realized because there is less mass of core material (thinner stators). The extent to which current resistance losses are increased versus reductions in Eddy current losses determines the efficiency. There is reason to believe that sufficient degrees of design freedom exist for optimal TheMotor designs to surpass the performance of contemporary motors in every aspect (including efficiency).

The 50% to 80% reduction in materials (and absence of permanent magnets) translates to significant reductions in cost, volume, and mass; all of which enable incredible impacts on contemporary and new motor applications.

Smaller “pancake” designs also enable integration of the motor directly into devices including wheels. It is possible to have wheels and propellers that combine motor, generator, braking, and application in one device.

The energy densities are much higher than contemporary designs.

Also, significant reductions in Eddy-current losses are realized because there is less mass of core material (thinner stators). The extent to which current resistance losses are increased versus reductions in Eddy current losses determines the efficiency. There is reason to believe that sufficient degrees of design freedom exist for optimal TheMotor designs to surpass the performance of contemporary motors in every aspect (including efficiency).

The 50% to 80% reduction in materials (and absence of permanent magnets) translates to significant reductions in cost, volume, and mass; all of which enable incredible impacts on contemporary and new motor applications.

Smaller “pancake” designs also enable integration of the motor directly into devices including wheels. It is possible to have wheels and propellers that combine motor, generator, braking, and application in one device.